Preventive maintenance

Condition monitoring is the process of monitoring a machine condition parameter in order to identify a significant change that is indicative of a failure, thus enabling machine maintenance to be scheduled or other measures to be taken to prevent damage or other consequences.

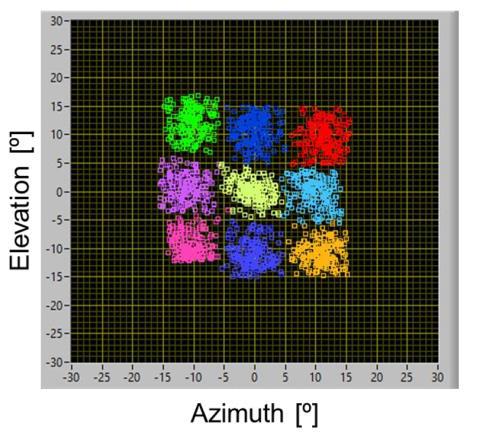

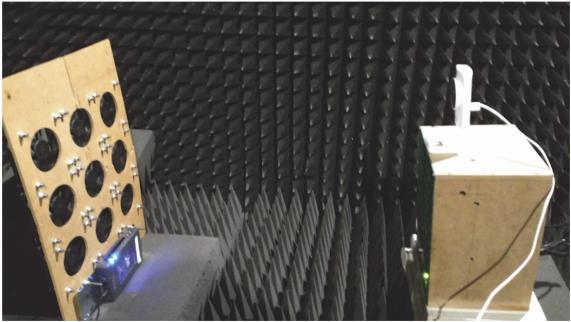

One of the classic approaches to condition monitoring of machinery condition is based on taking periodic measurements of equipment vibrations and comparing them with known healthy/damaged condition data to assess the condition of the equipment. Vibrational measurements require a machine-mounted sensor, such as accelerometers, and this presence can imply disturbances in machine response and performance. Since vibrations are related to acoustic emissions, a possible solution to this problem is the analysis of related acoustic, rather than vibrational, responses, since the sound field contains abundant information related to failure patterns. Some MEMS microphone arrays are specially designed for acoustic imaging of machines to detect possible malfunctions.

Related publications

| Título | Autores | Año | ISSN | Revista | Descargar |

|---|---|---|---|---|---|

| Comparison of Methodologies for the Detection of Multiple Failures Using Acoustic Images in Fan Matrices | Lara Del Val Puente; Alberto Izquierdo Fuente; Juan jose Villacorta Calvo. Luis Suarez | 2020 | 1875-9203 | Shock & Vibration, Hindawi. Volume 2020 | |

| Using a Planar Array of MEMS Microphones to Obtain Acoustic Images of a Fan Matrix | Izquierdo, A.; Villacorta, J.J.; del Val Puente, L.; Suárez, L. | 2017 | Hindawi | ||

| First steps on fan matrix condition monitoring andfault diagnosis using an array of digital MEMSmicrophones | Lara del Val Puente Alberto Izquierdo, Juan J. Villacorta, Luis Suárez, Marta Herráez | 2017 | Proceedings of Meetings on Acoustics, Vol. 30, 030014 (2017) |